A step by step walk through on how to cast you own small figures in white metal aka pewter.

|

| Items needed |

From this retailer:

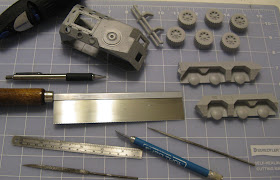

List of materials needed:

A heat resistant work area (I use the slab of green marble shown in this pic)

Mold Rubber $20.00

Mold Vulcanizer Tool $95.00

HDF or Masonite mold clamp boards $0.50

Heavy Duty spring clamps $4.00 (local DiY store)

Melting Pot $72.00

Pouring Ladle $6.00

10oz Ingot $7.50

Talc powder / baby powder $2.00 (wal-mart)

Heavy Duty gloves $4.00

Shipping $17.00

Total around $230 shipped to a US address

So understand its a hefty investment to be able to make 1 mold and cast 10oz worth of metal figures.

- If you mess up the mold making step you just cost yourself around $20.00. They have a bulk deal for 5 or more blanks each one is reduced to $15 each.

- To make 2 metal figures like the 2 small ones I used in this example uses 0.84oz of material, so you will get approximately 11.9 figures (obviously YMMV depending on what is cast). Good news is you can remelt miscasts.

- So to break even; assuming you buy one mold blank and 5 ingots ($260) you would need to cast 59 figures (barely possible) @ $5.00 retail ($295). However with all the reliable discount web stores offering %20 discounts and cheap/free shipping you are still in the hole in money spent and time used.

- So If you are thinking gee I wanna be a recaster and flood eBay and trading boards with high quality metal recasts of some other companies IP understand its probably not worth the effort and cost.

- If you want to make casts of your own creations that are worth selling at a premium price, this is probably a decent option for you.

I purchased my setup around mid 2001 and spent considerably less that the current costs. I wanted to finish out a very large army of high cost metal models that at the time were hard to get in the specific pose I wanted (random blister packs), and there was not reliable discounters. My break even point back then was around 45 models I wanted 60ish.

First Steps

- Place a new blank in the vulcanizer tool dust both sides of the tool with Talcum (or Baby powder), the uncured slabs are smaller than the cavity and will expand when heated causing rubber to squirt out of the tool like a hard toothpaste. Remember this when later when baking it, you will want a catch tray underneath the tool.

- Lightly place the original to be cast on one slab of the rubber, you may be able to place 2 small models on the slab leave around 1/4 inch of room to any edge and any other model.

- Because you obviously plan on casting you own designs know the following. A green stuff master can withstand 3 vulcanizations (per the kneadatite website). Also your GS master must not have a plastic core because of the time at the required heat and pressure.

- Once you have lain out where you think you want the models to go remove a small amount of the mold rubber making a cavity smaller than the master (around 1/3 of the volume of the original), you will repeat this on the other half of the mold rubber.

- Place 4 of the register keys into one side of the mold, all four facing the same way. The flat edge of these should be flush with the top of the slab of rubber that you push them into.

- You may also want to use a metal pour gate, instead of cutting it your self later from the cured mold.

- Now that the original(s) is on one slab lightly dust the slabs with Talcum powder.

- Close the tool, tighten the hex screws, and remove the wooden handles.

- Place in the oven at 400 degrees for an hour.

|

| Mold Vulcanizer & mold blank |

|

| register key nuts and pour gate |

|

| Mold blank & Vulcanized finished mold (top) |

|

| Open Vulcanizer with an uncured mold blank |

Cured Mold Prep

- Let the sucker cool down, be patient

- Remove the mold from the tool, this will be easier if you have a wooden stir stick / Popsicle stick. The mold has expanded to fit the cavity of the tool and will require some wrangling.

- Pry the halves apart and remove the masters.

- Cut your pour gates (how the molten metal gets into the cavity)

- Cut vents if this is your first mold try a casting or two and see if any area is not getting metal into it. This will usually be the ends of gun barrels or horns etc

|

| Completed mold with pour gates and vents cut |

|

| Cutting tool, used to remove cured rubber |

Hot Metal Time

- Have a heat resistant work surface and gloves, molten metal will eat your face/skin right off (Like the Honey Badger (Honey Badger doesn't give shit)

- Your mold needs to be hot, a cold mold will cause the molten metal to setup too fast and your pour won't fill in all the detail.

- Once you mold is hot if you are having miscasts then you might need to cut vents see photo above.

|

| 4lb capacity melting pot, ladle, and pewter ingot |